The impact of tariff policies on chemical industry companies

The impact of tariff policies on chemical industry companies is mainly reflected in cost increases, supply chain adjustments, changes in market demand, and changes in the international competitive landscape.

Cost increase and supply chain adjustment

The implementation of tariff policies has led to a significant increase in the import costs of raw materials for chemical industry companies. For example, the tariffs imposed by the United States on China have increased the import costs of Chinese chemical companies, especially those highly dependent on imported chemical raw materials such as specialty polymers, electronic chemicals, and agrochemical intermediates. The increase in these costs directly squeezes the profit margin of enterprises, forcing them to seek alternative suppliers or readjust their supply chain layout. In addition, the restructuring of the global supply chain has also led to an increase in logistics costs, further exacerbating the operational pressure on enterprises.

Changes in market demand and international competitive landscape

Tariff policies not only affect the production costs of chemical industry companies, but also indirectly impact their business operations by influencing market demand and international competition patterns. For example, the United States' policy of "reciprocal tariffs" globally has had a certain impact on China's chemical exports, especially those directly exported to the United States. However, China has partially offset this impact through countermeasures and increased demand in the domestic market, and even promoted the accelerated development of domestic alternatives in certain areas. In addition, the changes in the international competitive landscape have also prompted enterprises to strengthen their independent and controllable capabilities and increase their domestic market share.

Specific industry impact cases

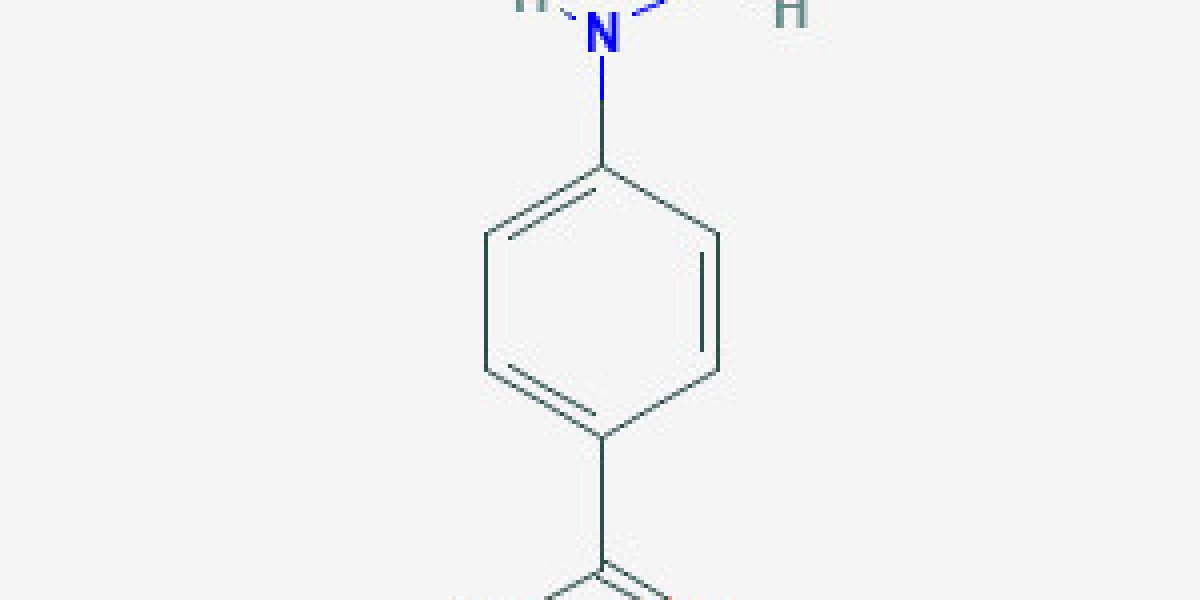

High end chemicals, such as specialty polymers and electronic chemicals, have seen a significant increase in costs due to their high dependence on imports and rising tariffs, which in turn affects the cost and supply chain stability of downstream manufacturing industries.

Agrochemical intermediates, such as key intermediates of glyphosate, have seen an increase in agricultural production costs due to increased tariffs, prompting local companies to accelerate alternative research and development despite facing patent infringement risks.

Resource based bulk chemicals: such as shale gas derived chemicals, the increase in tariffs has led to an increase in raw material costs, and companies need to find alternative suppliers or adjust production strategies.

Response strategies and suggestions

Faced with the impact of tariff policies, chemical companies can adopt the following strategies:

Diversified supply chain: Seeking multiple suppliers to reduce dependence on a single market.

Technological innovation: Reduce production costs and enhance product competitiveness through technological innovation.

Policy support: Utilize government provided policy support, such as tax incentives, subsidies, etc., to alleviate the burden on enterprises.

Market diversification: Expand domestic and international markets, reduce dependence on specific markets, and diversify risks.